The Pros and Cons of Polyester Filament Yarn for Bed Sheets: A Comprehensive Guide for Industrial Buyers

Table of Contents

- Introduction: The Rise of Polyester in Modern Bedding

- Understanding the Material: Polyester Filament Yarn Explained

- Key Advantages of Polyester Filament for Bed Sheets

- Critical Disadvantages and Limitations

- Comparative Analysis: Polyester vs. Cotton, Microfiber, and Blends

- Technical Specifications and Quality Grading

- Market Positioning and Target Consumer Segments

- Manufacturing Considerations for Sheet Producers

- Future Developments and Sustainability Concerns

- Strategic Recommendations for Procurement Decisions

- FAQ

1. The Pros and Cons of Polyester Filament Yarn for Bed Sheets . Introduction: The Rise of Polyester in Modern Bedding

For procurement managers and textile professionals, the choice of sheet material represents a critical intersection of cost, performance, and consumer preference. Polyester filament yarn has emerged as a dominant force in the global bedding market, representing approximately 38-42% of all sheet fibers sold worldwide (Textile World Data, 2025). This comprehensive analysis examines why this synthetic material has gained such prominence while providing a balanced assessment of its strengths and weaknesses. Understanding these factors is essential for making informed sourcing decisions that align with your product strategy and target market expectations.

2. Understanding the Material: Polyester Filament Yarn Explained

Polyester filament yarn for bedding is typically produced as fully drawn yarn (FDY) with specific modifications for comfort applications. Unlike spun polyester staple fiber, filament yarn consists of continuous strands that create a smoother surface. For sheets, manufacturers commonly use:

- Deniers: 50D to 150D, with 75D being most common for standard sheets

- Filament counts: 36F to 144F, with higher counts creating softer textures

- Cross-sections: Round, trilobal, or hollow fibers for different tactile properties

- Finishes: Various chemical treatments to enhance moisture-wicking, softness, or antimicrobial properties

3. Key Advantages of Polyester Filament for Bed Sheets

Durability and Longevity

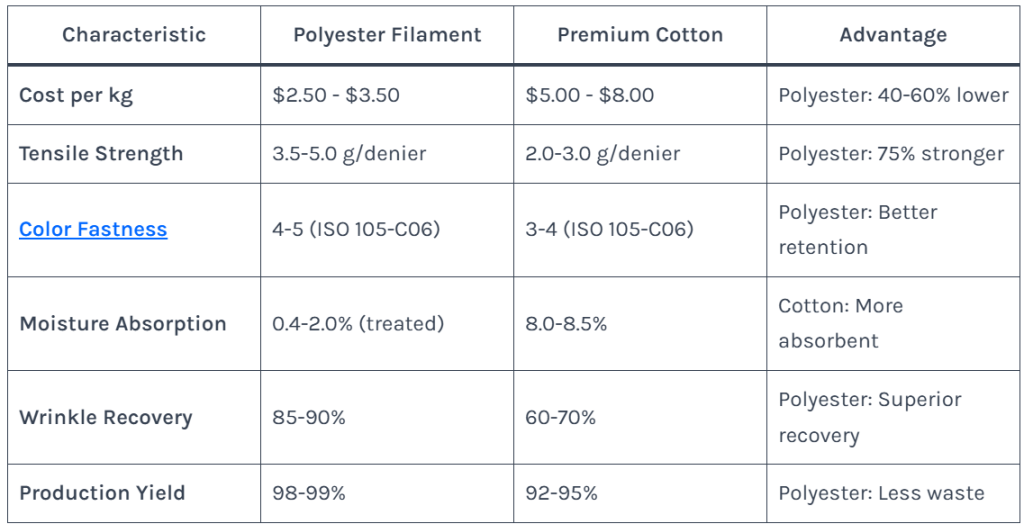

- Tensile strength: 3.5-5.0 g/denier, approximately 2-3 times stronger than cotton of equivalent weight

- Abrasion resistance: Withstands 25,000-40,000 Martindale rubs compared to cotton’s 10,000-15,000

- Color retention: Maintains 90-95% of color intensity after 50 washes versus 70-80% for cotton

- Dimensional stability: <3% shrinkage after multiple washes compared to 5-10% for untreated cotton

Performance Characteristics

- Wrinkle resistance: Inherent property requiring minimal ironing

- Quick drying: 30-50% faster drying time than natural fibers

- Moisture management: Modern moisture-wicking treatments transfer perspiration effectively

- Hypoallergenic properties: Naturally resistant to mold, mildew, and dust mites

Economic and Manufacturing Benefits

- Cost efficiency: Typically 40-60% less expensive than high-quality long-staple cotton

- Production consistency: Uniform properties with minimal batch-to-batch variation

- Supply stability: Not subject to agricultural uncertainties affecting natural fibers

- Design versatility: Can be engineered for specific weights, textures, and performance features

Table 1: Performance Comparison – Polyester Filament vs. Premium Cotton

4. Critical Disadvantages and Limitations

Comfort and Sensory Issues

- Breathability concerns: Lower air permeability (2-5 cm³/cm²/sec vs. cotton’s 8-12)

- Heat retention: Can sleep warmer, problematic in hot climates

- Static buildup: More prone to static electricity, especially in dry environments

- Initial stiffness: Often requires multiple washes to achieve optimal softness

Environmental and Perceptual Challenges

- Microfiber shedding: Releases 2-3 times more microfibers than cotton during washing

- Recyclability issues: Only 15-20% of polyester textiles are currently recycled

- Petroleum dependence: Derived from non-renewable resources

- Consumer perception: Viewed by some as “cheap” or “inferior” to natural fibers

Performance Limitations

- Moisture absorption: Naturally hydrophobic, requiring chemical treatments

- Heat sensitivity: Melts at 250-260°C (vs. cotton’s decomposition at 350°C)

- Pilling potential: Lower-quality versions may develop pills over time

- Oil-based stains: Difficult to remove compared to water-based stains

5. Comparative Analysis: Polyester vs. Cotton, Microfiber, and Blends

Polyester vs. Cotton

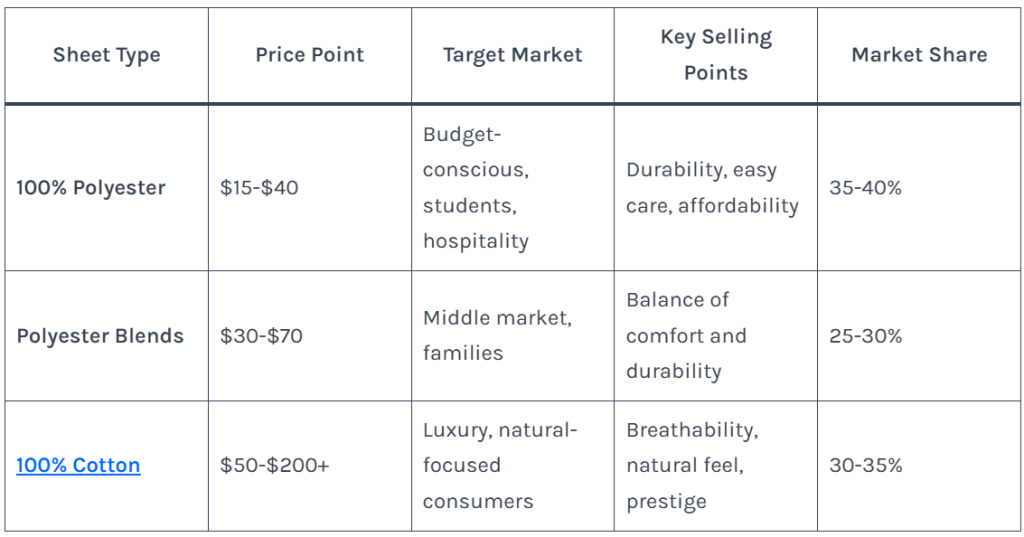

The fundamental trade-off: performance and cost vs. natural comfort and perception. Polyester excels in durability, consistency, and affordability, while cotton wins in breathability, natural feel, and market perception for luxury segments.

Polyester vs. Microfiber

Microfiber (typically 0.5-1.0 denier per filament) represents a specialized subset of polyester offering exceptional softness but at higher cost and with greater environmental concerns due to increased microfiber shedding.

Polyester-Cotton Blends

The 50/50 or 65/35 polyester-cotton blend represents a strategic compromise, balancing durability with comfort. Blends typically cost 20-30% more than 100% polyester but 25-40% less than 100% cotton.

Table 2: Market Position Analysis by Sheet Type

6. Technical Specifications and Quality Grading

Quality Tiers for Polyester Sheet Yarn

- Economy grade: 75D/36F, round cross-section, basic finish

- Standard grade: 75D/72F or 100D/144F, trilobal cross-section, moisture-wicking finish

- Premium grade: 50D/72F or 75D/144F, hollow or modified cross-section, multiple performance finishes

Critical Testing Parameters

- Yarn evenness: Uster CV% < 2.0% for premium applications

- Tenacity: Minimum 3.8 g/denier for sheet applications

- Elongation: 20-30% for optimal drape and durability

- Thermal stability: < 5% shrinkage at 60°C washing

7. Market Positioning and Target Consumer Segments

Primary Market Segments

- Hospitality industry: 70-80% of hotel chains use polyester or blends for durability and cost control

- Budget retail: Major discount retailers source 100% polyester for entry-level price points

- Performance bedding: Moisture-wicking properties target athletic and hot-climate consumers

- Healthcare facilities: Hypoallergenic properties suit sensitive environments

Consumer Preference Data

- Price sensitivity: 65% of consumers consider price the primary factor for basic sheet purchases

- Performance priorities: 45% rank “easy care” and “durability” as top requirements

- Material preferences: 60% express preference for natural fibers, but 70% purchase based on price/performance

8. Manufacturing Considerations for Sheet Producers

Weaving and Knitting Parameters

- Weaving: Plain, sateen, or percale weaves at 180-250 threads per inch

- Knitting: Warp knitting for stretch properties in fitted sheets

- Finishing: Calendaring for smoothness, raising for brushed effects, chemical treatments for performance properties

Production Efficiency Factors

- Fabric yield: 95-97% utilization versus 90-92% for cotton

- Production speed: 15-20% faster weaving/knitting than with cotton

- Color application: Superior dye uptake allows for shorter dyeing cycles

9. Future Developments and Sustainability Concerns

Innovation Frontiers

- Recycled polyester: rPET from bottles achieving 85-90% of virgin polyester performance

- Biodegradable variants: PHA-based polyesters under development but not yet cost-competitive

- Enhanced breathability: Advanced fiber engineering achieving 6-8 cm³/cm²/sec air permeability

- Smart functionalities: Phase-change materials and temperature regulation technologies

Environmental Initiatives

- Microfiber filtration: In-wash capture devices reducing microfiber release by 80-90%

- Chemical management: Bluesign® and OEKO-TEX® certifications becoming standard for premium lines

- Circular systems: Take-back programs and chemical recycling gaining industry attention

10. Strategic Recommendations for Procurement Decisions

When to Choose Polyester Filament

- Budget-constrained programs with < $40 retail price point

- Applications requiring maximum durability (hospitality, healthcare, rental)

- Markets with strong preference for easy-care, wrinkle-resistant properties

- Performance bedding with moisture-wicking or thermal requirements

When to Consider Alternatives

- Luxury positioning with > $80 retail price point

- Hot climate markets where breathability is paramount

- Environmentally conscious consumers willing to pay premium for natural/recyclable options

- Products targeting consumers with strong natural fiber preferences

Specification Guidelines

- For economy sheets: 75D/72F, round cross-section, basic softness finish

- For mid-market sheets: 75D/144F, trilobal cross-section, moisture-wicking finish

- For premium polyester: 50D/72F, hollow cross-section, multiple performance finishes

11. FAQ

Q1: Is polyester filament safe for people with sensitive skin or allergies?

A1: High-quality polyester filament with proper finishing is generally hypoallergenic and resistant to dust mites, mold, and mildew. However, some chemical finishes may cause irritation. Look for OEKO-TEX® Standard 100 certification to ensure safety for sensitive skin.

Q2: How does microfiber differ from standard polyester filament for sheets?

A2: Microfiber refers to ultra-fine filaments (typically <1.0 denier per filament) that create exceptionally soft fabric. While technically a type of polyester, microfiber offers superior softness but generally has higher cost and greater environmental concerns regarding microfiber shedding.

Q3: Can polyester sheets match the breathability of cotton?

A3: Recent advancements in fiber engineering, including hollow fibers and specialized fabric constructions, have improved polyester’s breathability to approach that of lower-thread-count cottons. However, 100% cotton generally maintains superior air permeability in equivalent constructions.

Q4: What is the typical lifespan of polyester sheets compared to cotton?

A4: With proper care, 100% polyester sheets typically maintain their appearance and integrity for 2-3 years of regular use, compared to 3-5 years for quality cotton. Polyester’s superior color retention often makes it appear newer longer despite potential fiber degradation.

Q5: How does recycled polyester (rPET) perform compared to virgin polyester?

A5: Modern rPET achieves 85-90% of the performance characteristics of virgin polyester, with minimal differences noticeable to consumers. The primary limitations are slightly reduced color vibrancy and approximately 10-15% higher cost due to collection and processing expenses.

Q6: What thread count is appropriate for polyester sheets?

A6: Because polyester filaments are continuous and finer than cotton fibers, direct thread count comparisons are misleading. A 180-thread-count polyester sheet may offer similar coverage to a 300-thread-count cotton sheet. Focus on fabric weight (90-120 GSM for sheets) and denier per filament rather than thread count alone.

Q7: How can I reduce pilling in polyester sheets?

A7: Specify higher filament count yarns (144F vs. 36F), use longer staple fibers if using spun polyester, employ anti-pilling finishes, and recommend proper consumer care (gentle wash cycles, avoid high heat drying). Higher-quality polyester with finer filaments naturally pills less.

Q8: Are there fire safety advantages to polyester sheets?

A8: Polyester is inherently more flame-resistant than cotton, melting rather than burning freely. However, most sheets of either fiber type require flame-retardant treatment to meet commercial standards. Untreated polyester has a higher melting point than cotton’s ignition point but can still pose fire risks.

Q9: How does polyester’s environmental impact compare to cotton’s?

A9: The comparison is complex. Polyester production uses less water but more energy and derives from non-renewable resources. Cotton is renewable but water-intensive and pesticide-dependent. Lifecycle analyses show varying results depending on measurement criteria. Recycled polyester significantly improves the environmental profile.

Q10: What innovations are coming that might change polyester’s value proposition for sheets?

A10: Key developments include truly biodegradable polyesters, enhanced breathability through fiber architecture, embedded temperature regulation technologies, and improved chemical recycling systems. These innovations may address current limitations around environmental impact and comfort perceptions.